TOP centre swath rakes with four rotors

Professional series from 8.00 to 12.50 m working width

Short harvesting windows necessitate productive harvesting technology. With the professional TOP C s-line series, we offer powerful centre-swath rakes with the highest possible harvesting performance.

| TOP 1252 C | |

| Working width | 8 – 12,5 m |

| Working width adjustment | Hydraulic |

| Swath width | 1,2 – 2 |

| Rotor diameter | 3,3 m |

| Rotor diameter front / rear | 3,3 / 3,3 |

| Transport width | 3 m |

| Transport height | 3,99 m |

| Transport length | 10,25 m |

| Parking height without tine arms removed | 3,99 m |

| Parking height with tine arms removed | 3,4 m |

| Tine arms per rotor | 13 pcs. |

| Tine arms per rotor rear / front | – |

| Removable tine carrier arms per rotor | 13 pcs. |

| Tines per tine arm | 4 pcs. |

| Rotor unit | TOPTECH PLUS |

| Driveline speed with grass header | 540 rpm |

| Weight | 6315 kg |

| Power requirement | 90 hp |

| Mounting | Trailed hydraulic folding |

| Rotor wheels | Pivoting |

| Tyres – chassis | 500/50-17 |

| Swath placement in direction of travel | middle |

| Height adjustment system | Crank handle adjuster |

| Rotor tyres (standard) | 16 x 6,5-8 |

| Jockey wheels | Inner jockey wheels on all rotors |

| Wide angle P.T.O. | Wide-angle PTO shaft on one end |

Contact Us

Standard Equipment

-

TOP C

Mounting Trailed hydraulic folding Mounting option 3 point linkage with pins Mounting category Cat. II / 2 PTO shaft guarding with cam clutch PTO shaft profile 1 3/4″ 6-splines Hydraulic connection 1 x double acting for the lifting system 2 x double acting for the working width adjustment

1 x Load-Sensing with POWER CONTROL

1 x single-acting with free flow return line with POWER CONTROL

Electrical connection 1 x 7-pin lighting plug for warning signs with lighting 1 x 3-pin Cobo plug for the control system

Standard equipment includes Operator’s manual Spare parts list

Inner jockey wheels on all rotors

Technology

-

Benefits

Avoiding a backlog during harvesting demands highperformance agricultural technology. The performance of silage trailers and self-loading wagons can be increased by up to 20% if the swath is of optimal shape and uniform density.

Unique hybrid drive

Working widths

PÖTTINGER has developed a unique hybrid drive technology: four-rotor rake.

- Hydraulic drive at the front, mechanical drive at the rear.

- The working width can easily be adjusted from 8.0 to 12.50 m.

- Raking around obstructions is no problem.

- The raking width can even be adjusted while working thanks to the pivot wheels.

TOPTECH PLUS

This impressive and proven rotor technology from PÖTTINGER is now also integrated in the four rotor rake.

- The whole tine arm can be exchanged quickly and easily in the event of any damage.

- Just undo two bolts to slide the tine arm plus cam roller out of the rotor casing.

- No problems with oil leaks.

- Ready for action again in no time.

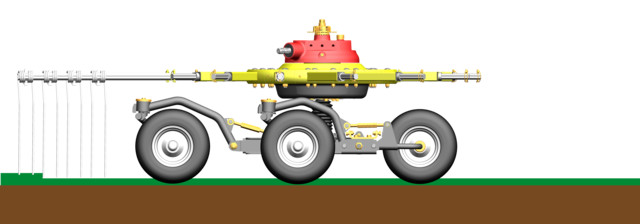

From the field to the road without leaving the cab

Transport position

TOP 1252 C- The hydraulic drive of the front rotors enables the extending arms to be pivoted inwards for a transport height of only 3.99 m without removing tine arms or folding safety guards. Annoying setup times are therefore a thing of the past.

- Large dimensioned 500/50-17 tyres minimise pressure on the ground in the field while maximising driving comfort on the road.

- Optionally available are 620/40 R 22,5 or 710/35 R 22,5 tyres.

- Choose between pneumatic or hydraulic brakes.

- Mechanical interlock and support for safe road transport.

-

PÖTTINGER ground hugging technology

PÖTTINGER ground hugging technology meets the very highest expectations. There is no better solution. The result is tidy raking work at the same time as protecting.

Tidy and protective raking

Tandem axle

- The tandem axles are fitted with large 16 x 6.5-8 pivoting wheels.

- Pentagonal chassis (5 wheels) for inside the sweep of the tines are standard.

- The MULTITAST ground hugging wheels with anti-wrap guards can be fitted as an option and – together with the floating rotor suspension – guarantee precision guidance of the tines over undulations.

- Because the tandem axles are adjustable, the angle of the rotors can be adjusted precisely to the operating conditions in just a few minutes.

Operating comfort

MULTITAST

- One double-acting remote is for lifting the rotors and two doubleacting remotes are used to adjust the working width.

- An especially convenient electronic POWER CONTROL terminal is available as an option for lifting the rotors individually and adjusting the rotor height hydraulically.

- Also an especially convenient electronic terminal is the CCI ISOBUS terminal with all functions of POWER CONTROL and more.

-

TOPTECH PLUS

Impressive rotor technology

TOPTECH PLUS

The large cam tracks on PÖTTINGER rakes offer a cam track diameter of up to 420 mm and a bearing spacing of up to 900 mm on the tine arms. These properties give the tine arms maximum strength with minimum stress on the arm bearings. The cam track can be infinitely-variable adjusted to different forage volumes and changing harvesting conditions. The rotor gears run in a sealed semi-liquid grease gearbox.

Rotor unit encapsulated and dust-tight

No lubrication required. TOPTECH PLUS eliminates leak problems and requires no oil checks or oil changes.Maximum uptime and durability

TOPTECH PLUS rotorsOptimised for smooth control of cam rollers. No sudden inclines in cam track so control arm follows cam track smoothly. Maintenance-free steel cam rollers, high strength cam shafts and wide spacing of the tine arm bearings guarantee high strength and low stress to the bearings. Additionally, the tine arm bearings are also maintenance-free.

The heavy-duty tine arm cross-section is strong and resistant to twisting and bending. Tidy raking work is provided by 10 to 15 tine arms per rotor, depending on the working width. The tine arms are removable to reduce height for transport and parking.

Service-friendly rotor technology

Tine change

The whole tine arm can be exchanged quickly and easily in the event of any damage. Just undo two bolts to slide the inner tine arm and roller out of the rotor casing.

- No problems with oil leaks.

- Ready for action again in no time.

-

TOPTECH PLUS - Best forage

Best forage

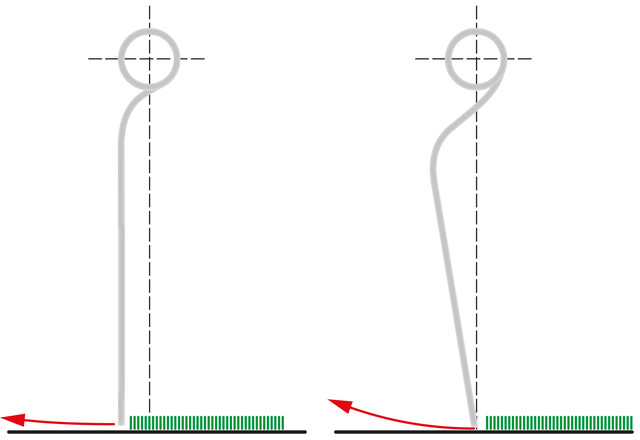

Raking has a decisive influence at the end of the harvest chain on how clean the forage remains. The tines must not contact the ground; instead they rake the forage carefully out of the sward.

TOP tines deliver millimetre precision

Tines

The tines are positioned straight at the ground directly under the tine arm, without any need for a steep offset angle. Due to the resistance of the forage, they are pressed back slightly but do not rise upwards under load therefore the tines produce exact raking results. These tines do not need to be set so deep as others to rake tidily. This means less stress on the cam track and cam rollers. Resulting in both the sward and forage are both treated with care. The long tines are drawn smoothly out of the swath for a perfect swath shape.

Easy height adjustment

Height adjustment

The working height of TOP rakes can be adjusted from the standing position using a hand crank. This is easily accessible and maintenance-free. A height indicator makes it easy to ensure that both rotors are the same height on twin rotor rakes.

Multi-stage raking

TOP tines

The outer pairs of tines are slightly shorter so that they do not contact the full volume of forage and the load is lower. The three inner pairs of tines are used for precision work.

Safe and sound

Tine security

Tine armsSecurely bolted

Featuring a shaped support disc, the tine mounting provides a secure connection.

Tine security system

The tine security system prevents tine loss in the swath. The safety tab is secured reliably over the outermost tine bolt.

Unbeatable tine arm profile

Extremely resistant to twisting and bending forces, which are dissipated along the edge sections. The linch pin is only a security measure. Easy to slot in, it is not possible to fit the wrong way. The inner tine pairs are also easy to install. All tine arms can be removed to save space when parked.

- MACHINERY

- NEW MACHINERY

- USED MACHINERY

- STIHL SHOP

- Segway

- OUR BRANDS

- SPECIALS

- FINANCE

- SERVICING

- BOOK A SERVICE

- CALL 1800 436 3673

- PARTS

- CONTACT US

- 1800 436 3673

- DIRECTIONS

- ABOUT US

- BRANCH LOCATOR

- MEET THE TEAM