HIT T high output trailed tedders

From 8.60 to 12.70 m working width

Trailed HIT T tedders from PÖTTINGER combine high output with intelligent technology. All of our models feature refined lifting geometry. This means you can raise the tedder into the headland position quickly and easily.

Technical data

| HIT 8.9 T | HIT 10.11 T | HIT 12.14 T | |

| Working width | 8,86 m | 11 m | 13,2 m |

| Working width DIN | 8,6 m | 10,6 m | 12,7 m |

| Transport width | 2,9 m | 2,9 m | 2,9 m |

| Transport height | 2,7 m | 2,7 m | 2,7 m |

| Parking height | 2,7 m | 2,7 m | 2,7 m |

| Weight | 1750 kg | 2095 kg | 2375 kg |

| Power requirement | 60 hp | 75 hp | 75 hp |

| Number of rotors | 8 pcs. | 10 pcs. | 12 pcs. |

| Number of arms per rotor | 6 pcs. | 6 pcs. | 6 pcs. |

| Type of tines | unequal leg length | unequal leg length | unequal leg length |

| Quality of tines | Super C | Super C | Super C |

| Tine security system | HEAVY DUTY as standard | HEAVY DUTY as standard | HEAVY DUTY as standard |

| Transmission | PTO shaft | PTO shaft | PTO shaft |

| Rotor diameter | 1,42 m | 1,42 m | 1,42 m |

| Wide angle P.T.O. | Wide-angle PTO shaft on one end | Wide-angle PTO shaft on one end | Wide-angle PTO shaft on one end |

| Tyres – rotor outside / inside | 16 x 6,5-8 / 16 x 9,5-8 | 16 x 6,5-8 / 16 x 9,5-8 | 16 x 6,5-8 / 16 x 9,5-8 |

| Tyres – chassis | 260/70-15,3 | 340/55-16 | 340/55-16 |

Contact Us

Standard Equipment

-

HIT T

Mounting Trailed hydraulic folding Mounting option Towing eye Tractor drawbar

PTO shaft guarding with cam clutch and free-wheel PTO shaft profile 1 3/8″ 6-splines Hydraulic connection 1 x single-acting for the lifting system 1 x double acting for the lifting system

Electrical connection 1 x 7-pin lighting plug for warning signs with lighting Standard equipment includes Operator’s manual Spare parts list

Tine cover

Technology

-

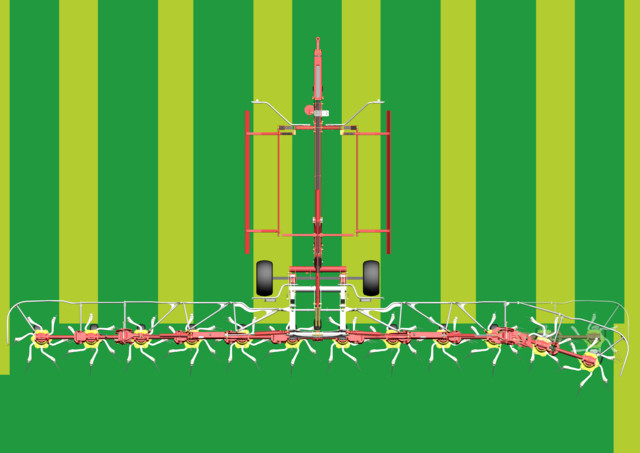

Trailed high output tedders

The trailed HIT T tedders with eight, ten and twelve rotors are designed for really large areas. To meet the requirement of wider wide working width and still provide the best possible ground tracking, the rotor units are linked together by hinges. Combined with the chassis guiding the rotors, HIT T tedders guaranteed a perfect job even at higher working speeds.

Maximum output

To harvest top quality forage in large fields within the shortest time, high performance tedders are needed to follow high output mowers. That is why there is an increase in demand for tedders with an ideal rotor diameter and wide working widths to deliver the best spreading quality. The working widths of 8.60 m, 10.60 m and 12.70 m meet the demand for high output in full. The optimum configuration of the DYNATECH rotors in combination with the chassis, ensures a perfect spread pattern.

-

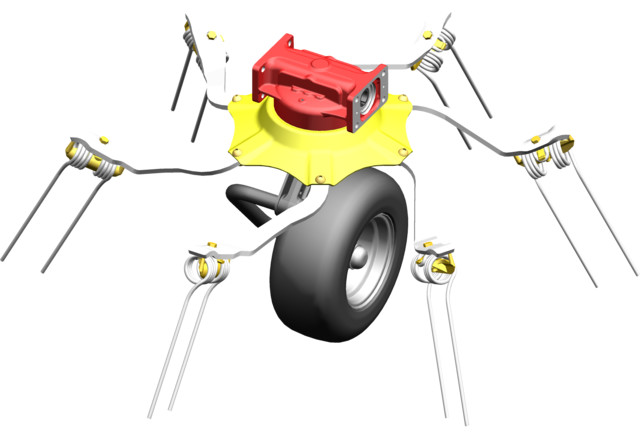

DYNATECH The new rotor technology

Yet another PÖTTINGER innovation: The unique swept-back tine arms guarantee a tidy distribution pattern. High performance is built in to our mounted and trailed HIT tedders.

DYNATECH for all HIT models

Rotors with a diameter of 1.30 m and five arms are ideal for young, short forage. Rotors with a diameter of 1.42 m or 1.67 m and six arms are designed for different working widths and operating conditions.

Four times as clean

- Forage pick-up – small rotor diameters guarantee clean crop pick-up

- Forage – optimum ground tracking of each rotor for clean forage

- Spread pattern – ideal spreading angle for a uniform blanket of clean forage

- Machine – no snagging thanks to the sleek design of the rotor units

The curved shape of the tine arms is unique.

Guiding the tines in a sweeping movement means less stress on the bearings. At the same time the trailed tines move more smoothly, are softer and handle the forage more carefully. The curved shape prevents forage from building up in the tine arms and wrapping around the rotors.

-

HEAVY DUTY tines

More safety

- The bolted mounting ensures a secure fit.

- A tine security system is standard – to cover all eventualities.

Tines with a longer service life

- An arched mounting supports the tine springs.

- Plenty of space between the tine springs and the tine arms allows for the best elasticity and movement.

- Strong Super-C quality tines.

Clean forage

Offset tine lengths pick up the forage uniformly and contribute significantly to improved tedding quality. Choose between two angles by rotating the mounting through 180°. The cleanest possible forage is guaranteed.

High-strength tine arm mountings

The rotor plates are made of heavy-duty, thick-walled pressed components with precise placement for the tine arms. In addition, the tine arms are also bolted to the rotor hubs to ensure an extremely secure mounting.

The tines and tine arms are subject to the highest stress during tedding. The solid flat bar tine arms feature indentations to ensure that the tines remain securely in place.

-

Mounting and transport

Universal drawbar

Lower linkage drawbar

Universal drawbar for high or low hitches

The advantages of the trailed PÖTTINGER tedder generation starts with the drawbar.

The bolted universal drawbar can be rotated 180° to match high or low hitches. A range of towing eyes and ball couplings are also available.

Lower linkage mounting

Lower linkage mounting is available as an option to provide really tight cornering capability. The machine can then follow the tractor’s path with even more precision.

Compact and safe during transport

Hydraulic functions only require one single-acting and one double-acting remote on the tractor. The ingenious stepping control valve system makes your work a great deal easier. The side guard folds in and out automatically. A large main frame with a strong rotor support and low-slung centre of gravity make it possible to transport the machine at high speeds on roads without swaying. This is also helped by the large 260/70-15.3 tyres (340/55-16 optional). Warning signs and road lights are standard.

-

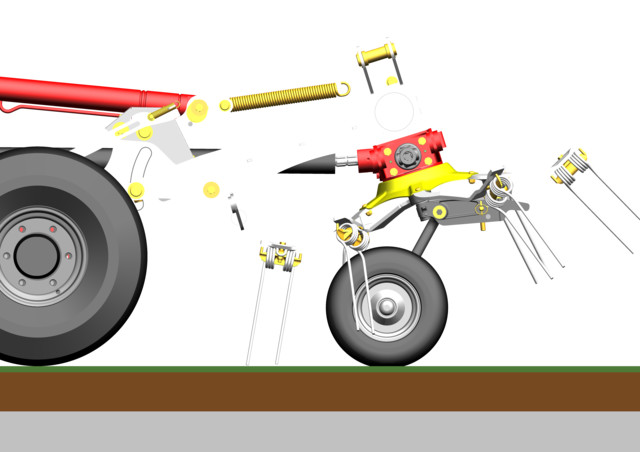

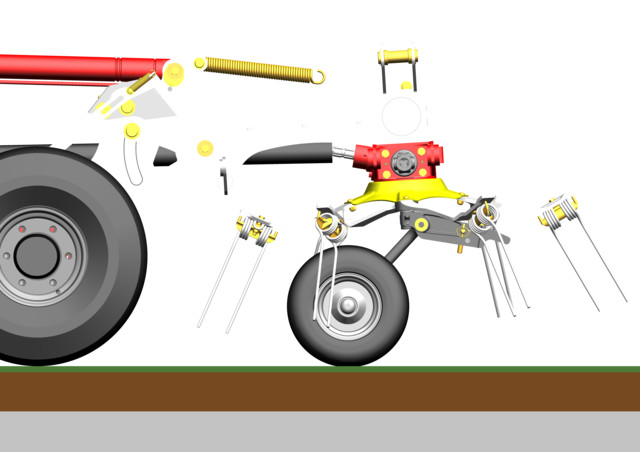

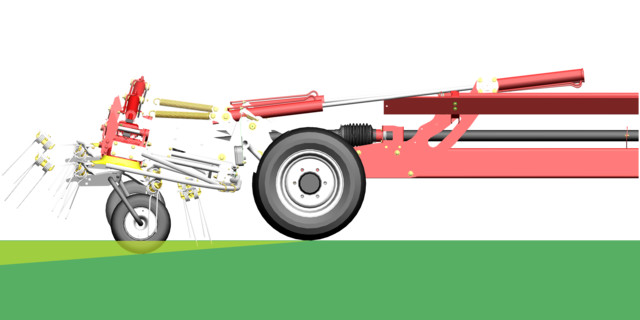

LIFTMATIC PLUS

Unique headland position

Clean forage is the highest priority in the harvest chain and results in higher milk and livestock yields. To makes sure that the forage stays clean, the optimum working height of the tedder rotors can be adjusted quickly and easily. You will be impressed with the advanced lifting technology on the HIT T – LIFTMATIC PLUS.

Unique headland position

Before being raised, the rotors are positioned horizontally by a guide system and then lifted. This ensures that the tines do not scrape against the ground.

- High headland position with 90 cm ground clearance.

- The forage remains clean and the sward is protected.

Straightforward rotor height adjustment

One hand crank enables the height to be adjusted from a central point. Easy access makes it easy to perform this important adjustment and saves you time. Rapid and accurate rotor height adjustment protects your soil and the forage.

-

Technology

Backlash-free drive joints

Sealed single and double constant velocity joints ensure consistent, smooth, backlash-free transmission. This ensures that the tines pick up the crop at a precise frequency and distribute it evenly. At the same time, they can be rotated in any position, eliminating the possibility of operator errors.

Rugged construction for long service life

The rotors are bolted securely to the frame. As a supporting element, the front guard rail also increases stability. Each rotor unit frame is connected to wide frame hinge for perfect ground tracking.

High quality fenceline tedding system with eight, ten and twelve rotors

Forage distribution

Hydraulic fenceline tedding system optional

The two rotors on the outer right-hand side are pivot hydraulically to the rear by 15°. The two diagonal rotors distribute the forage over the mown area without forming a ridge, unlike swath curtains.

- The two diagonal rotors distribute the forage over the mown area without forming a ridge.

- The result is a strip of cleared field bordering the neighbouring crop.

- This adjustment is made conveniently from the driver’s seat using a double-acting hydraulic cylinder.

-

Ground adaptation

Best ground tracking even with wide working widths

On the large trailed tedders with 10 and 12 rotors, the big chassis wheels are aligned just in front of the tine path to provide a ground tracking system for the rotors. For perfect ground tracking each rotor unit frame is connected to wide frame hinge.

Combined with the chassis wheels guiding the rotors, HIT 8.9 T, HIT 10.11 T and HIT 12.14 T tedders guaranteed to do a perfect job even at higher working speeds.

The large chassis wheels are close to the leading arc of the tines and therefore serve as jockey wheels for the rotors. Combined with the ideal rotor diameter, this ensures top distribution quality.

All rotor units on the HIT 8.9 T, HIT 10.11 T and HIT 12.14 T are equipped with hinged joints for perfect ground tracking.

Clevis-type frame hinges are fitted with plain bushes and are easy to lubricate. They provide each rotor the freedom of movement for constant forage pick up even on rough ground.

The frame and chassis do not put any load on the rotors As a result the weight is evenly distributed to all rotor tyres.

The two inner rotors on the HIT 8.81 and HIT 8.91 are fitted with 16 x 9.50-8 flotation tyres. This improves weight distribution during operation.

- MACHINERY

- NEW MACHINERY

- USED MACHINERY

- STIHL SHOP

- Segway

- OUR BRANDS

- SPECIALS

- FINANCE

- SERVICING

- BOOK A SERVICE

- CALL 1800 436 3673

- PARTS

- CONTACT US

- 1800 436 3673

- DIRECTIONS

- ABOUT US

- BRANCH LOCATOR

- MEET THE TEAM