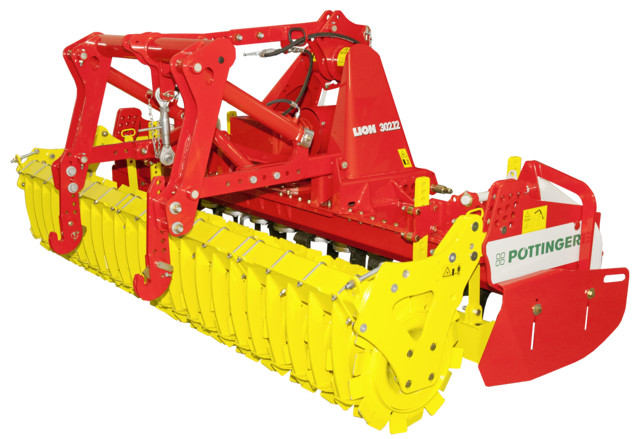

LION 1000

Foldable power harrows in heavy duty serie – 5 to 6 m working width

http://www.poettinger.at/en_au/Produkte/Detail/630/lion-1000

Technical data

| LION 5000 | LION 6000 | |

| Compare | Compare | |

| Working width | 5 m | 6 m |

| Rotor | 16 pcs. | 20 pcs. |

| Driveline speed with grass header | 1000 rpm | 1000 rpm |

| Rotor speed | 342 rpm | 342 rpm |

| Tine dimensions | 18 x 340 mm | 18 x 340 mm |

| Power requirement | 160 – 270 hp | 180 – 270 hp |

| Transport width | 2,7 m | 2,7 m |

| Weight of basic version | 2090 kg | 2267 kg |

| Weight cage roller Ø 540 mm | – | 650 kg |

| Weight toothed packer roller Ø 500 mm | 784 kg | 920 kg |

| Weight toothed packer roller Ø 500 mm coated | – | 926 kg |

| Weight toothed packer roller Ø 550 mm | – | 1056 kg |

| Weight pack ring roller Ø 550 mm | 1000 kg | 1100 kg |

Standard Equipment

LION 5000 / 6000

| Mounting | Rear three-point |

| Mounting option | 3 point linkage with pins |

| Mounting category | Cat. III / 3 |

| Rotor unit | Tapered bearings |

| PTO shaft guarding | equipped with a cam-type clutch |

| PTO shaft profile | 1 3/8″ 6-splines |

| Hydraulic connection | 1 x double acting |

| Standard equipment includes |

Rear levelling board Foldable side boards |

988

*Always confirm model specifications & pricing with a Gendore Product & Sales Specialist

Contact Us

Technology

-

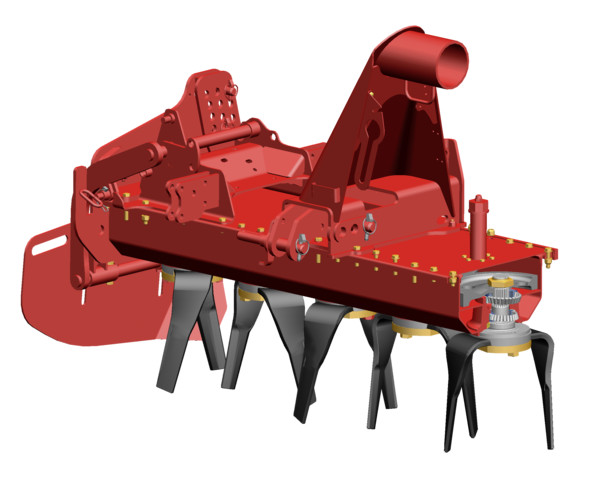

The rotor transmission, the heart of the machine

The rotor transmission, the heart of the machine

The rotor transmissionLION power harrows guarantee extremely smooth running and high strength. These machines operate reliably even in the hardest conditions and heaviest soil. Just take a look at this impressive technology- Thick-walled gear trough made of fine-grained steel – extremely resistant to twisting.

- Tapered front edge – soil can flow past unrestricted without bulldozing.

- Large gears feature integrated bearings. Extended inner splines for a secure seat on the rotor shaft.

- The bearing housings are welded to the central gusset and bottom of trough. An exact spacing between each rotor is guaranteed as a result.

- Robust tapered roller bearings in forged, single-piece bearing housings.

- The lower bearings are located as close as possible to the tine carrier, helping to reduce lateral stress.

- The upper and lower bearings are spaced as far apart as possible to reduce load and minimise stress.

- The forged, full-width tine carriers are integrated into casing. This offers the best protection against wrapping because the tines deflect the soil away from the gear trough. As a result stones cannot become trapped between the rotors.

Impressive driveline

- 1.97″ / 50 mm diameter rotor shafts on LION 103 series.

- 2.36″ / 60 mm diameter rotor shafts on LION 1002 series.

- Bearings and gears run submerged in semi-liquid grease.

- Labyrinth rotor shaft seals.

- The tines are 0.71″ / 18 mm thick and can be reversed to be used on both edges.

- 0.59″ / 15 mm thick tines on LION 303.12 / LION 353.14 series.

- Quick-fix tine replacement system optional.

-

Quality

Quality

Precision in every detail

Gear trough

Tine mountingsExtended service life is only possible thanks to precision machining and strong construction. At PÖTTINGER this level of high quality goes without sayingGear trough and tine mountings- The high-strength deep gear trough provides the gearbox with excellent torsional strength.

- Large toothed gears, 1.97″ or 2.36″ / 50 or 60 mm thick rotor shafts with heavy-duty tapered roller bearings and wide bearing spacing ensure durability

- The deep gear trough is formed from a single piece of steel. The welded central gusset provides maximum stability.

- The bearing housings are welded into the box section before milling at the CNC machining centre. This ensures exact rotor-to-rotor spacing and guarantees you smooth-running and a long service life.

- Forged components from the PÖTTINGER hardening centre offer many years of reliability.

Durable bearings

Durable bearingsThe bearings and gears are sealed and run submerged in semi-liquid grease. The tough bevel gears are made from tempered steel. The lower bearing is located close to the tine carrier. This takes the stress off the bearing and reduces wear. The shaft and bearing are protected by a labyrinth seal, which prevents loss of semi-liquid grease and at the same time ensures no dirt can penetrate.Tines hardened completely through

Tine mountingsThe tines are the critical interface to the seedbed. Penetration of the ground is optimised for the most uniform tilth.- LION power harrow tines are swept inwards and angled to the rear. As a result the soil near the surface is loosened and crumbled intensively. Larger clods remain lower down.

- The 18 x 340 mm thick tines are made from hardened boron steel and are heat treated right through the complete cross section.

- Both tines are seated securely in the recesses in the tine carrier. Two alignment pins keep the tines centered and they are secured using a clamping plate.

- Only two bolts are needed on each rotor. These can be loosened without chocking the rotors.

DURASTAR tines – coated and proven in the field

DURASTAR tines- 60 % longer service life thanks to special hard wearing coating

- 0.59″ / 15-mm and 0.71″ / 18-mm-thick reversible tines

- Excellent retention of shape

- Consistent work quality

-

Technology at the highest level

Technology at the highest level

Quick-fix tines

Quick-fixThe rapid and reliable solution available as an option- Remove lynch pin and lock pin

- Remove tines

- Fit new tines

- Refit lock and lynch pin – finished!

Universal tines for every operation

Flexible positionThe tines can be positioned aggressively pointing forwards, or in a trailing position. Either position achieves excellent tilth at seed placement level.Sweeping position – for good crumbling effect at seed level- Finer soil is concentrated at the level of the seed. Larger clods and harvest residues remain on the surface to protect against erosion.

Aggressive position – for breaking up the ground

- Angled forwards the tine breaks up the soil from underneath for mulch drilling, mixing harvest trash well into the soil.

- Only possible with the 0.71″ / 18 mm thick tines.

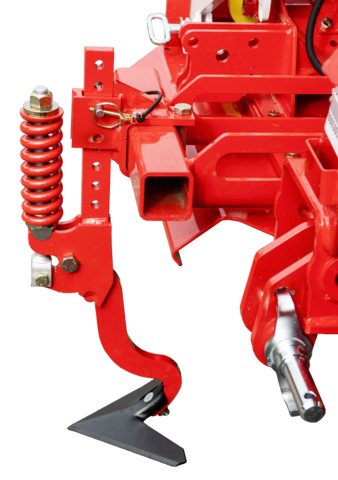

Robust linkage

Robust linkage- The linkage is widely supported. Double-sided Category 2 and 3 free swinging lower linkage and three position adjustment are designed to bring the power harrow as close as possible to the tractor.

Gearbox versions

LION lever change variable speed gearbox up to 270 hp

LION 5000, LION 6000

-

Standard & Optional Equipment

Standard & Optional Equipment

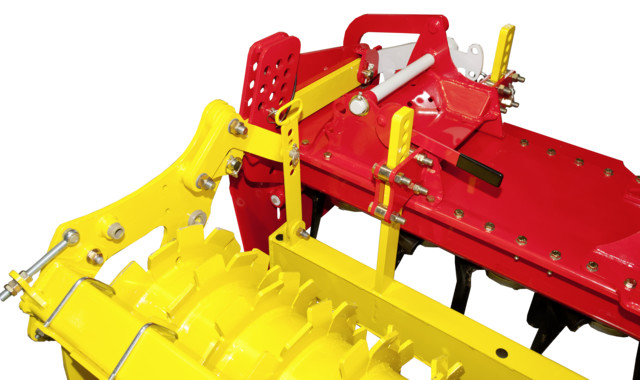

Levelling Board

Levelling BoardThe rear levelling board is standard and is set automatically with the depth of the rear roller – no readjustment is necessary. Consistent distance from the tines over the full working depth range thanks to linear guides on frame.- Initial depth set using pin-in-hole adjustment.

- This is easily accessible from the side.

The front levelling board (optional) is identical to the rear board.

Field-proven rear rollers

Rear rollers- Conveniently the scrapers can be adjusted from a central point as well as individually.

- A POTTINGER seed drill can be mounted directly to the rear roller and top link. The result is the seed drill and roller work as one follow ground contour changes exactly. Closely mounted to the roller scraper bar keeps overall length to a minimum.

- Coated hard wearing scrapers are standard on 19.68″ / 500 and 21.65″ / 550 mm tooth-packer roller, crumbling-packer roller, pack ring roller and rubber packer roller.

Wheel track eradicators

Wheel track eradicatorsSpring-mounted track eradicators are on all LION power harrows. These are spring-mounted to protect against stones and foreign objects. The working depth can be adjusted without using any tools. -

Mounting and linkage configurations

Mounting and linkage configurations

Reducing costs is top priority in arable farming. Save money with a power harrow/seed drill combination.

HYDROLIFT

HYDROLIFT- Hydraulic mounting system for independent seed drills with eight and length adjustable linkage.

- Two hydraulic cylinders guarantee maximum lifting power up to 52.91 sht / 2.4 t for larger mounted seed drills.

- Lift height limiter optional.

Implement mounted with a mechanical top link.

Implement mounted with a mechanical top link

Mounted seed drill- VITASEM and AEROSEM seed drills from PÖTTINGER can easily be mounted.

- The centre of gravity is in front of the rear roller – very close to the tractor. The additional weight of the seed drill on the roller provides even better consolidating effect for the seedbed. The gap between the coulter rail and the rear roller is minimised to form a compact unit.

- The piggy-back drill is mounted on the packer roller and guided by the top link using a parallelogram so the packer and seed drill form a single unit. This enables the working depth of the power harrow to be changed by adjusting the roller without having to correct the seed drill top link.

Piggy-back with hydraulic top link

Piggy-back with hydraulic top link- A hydraulic cylinder is also available to pivot the seed drill up over the power harrow.

- Improved of centre of gravity in relation to tractor.

- High ground clearance of drill coulters at headlands.

-

Rear rollers

Rear rollers

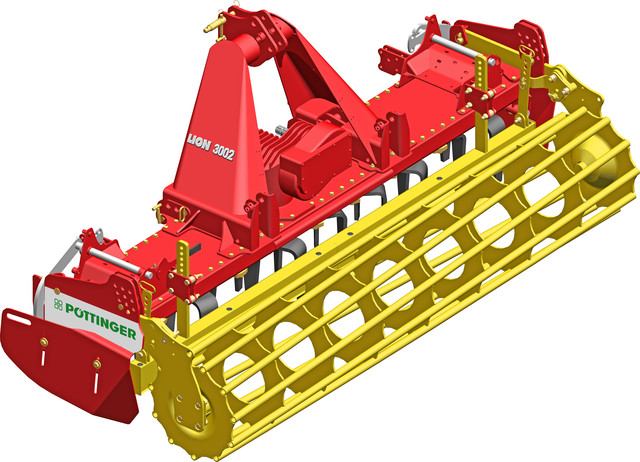

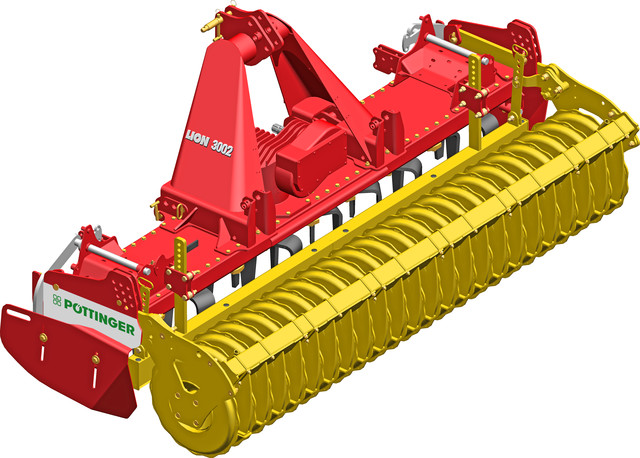

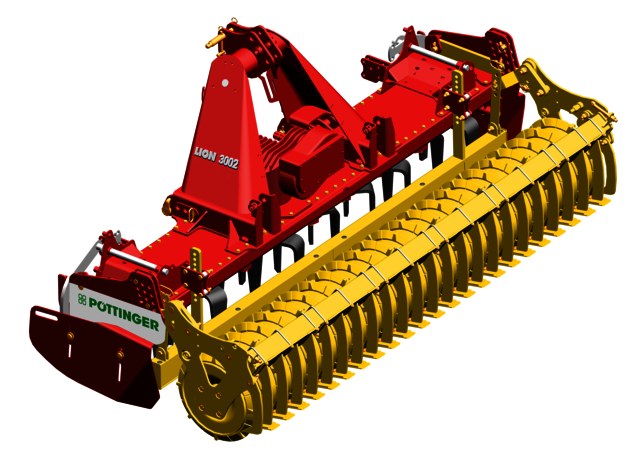

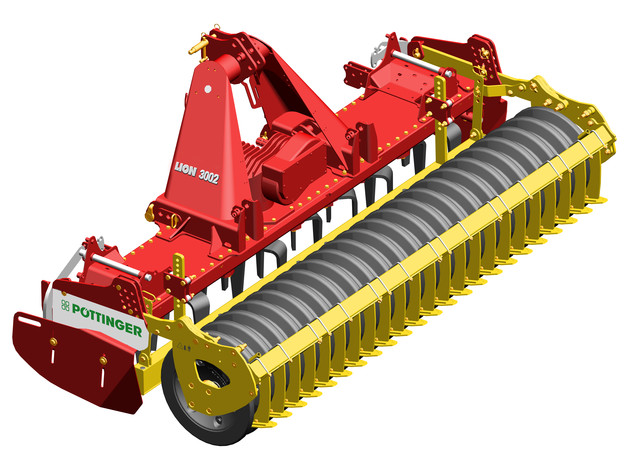

Cage roller

Cage rollerThe ideal roller for dealing with dry, non-sticky soils. The roller is fitted with strong rods for optimal compression.Diameter: 420 mm, 8 barsDiameter: 540 mm, 11 barsToothed packer roller

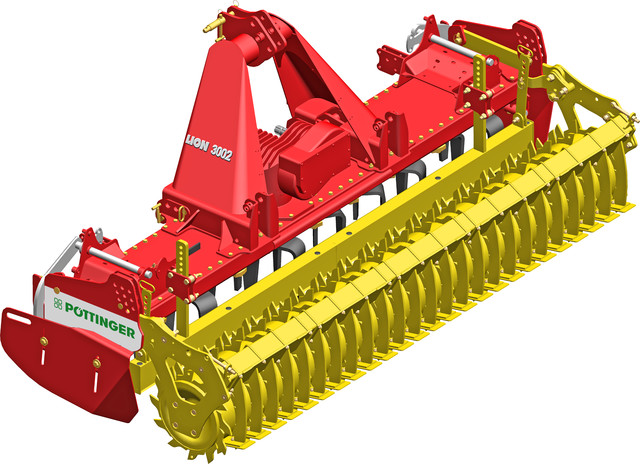

Toothed packer rollerThis roller is suitable for all types of soil. The roller leaves behind an optimum, re-packed seedbed with loose, fine soil at seed level. The scrapers are located just above surface level. That is why no earth clods can be lifted away, even in wet conditions, and a perfect capillary structure remains intact for optimum germination. The scrapers can be adjusted centrally and individually. They can simply be pivoted away for cleaning. The hardened scraper plates are reversible for double the service life. Roller diameter: 16.5″, 19.7″ and 21.7″ / 420, 500 and 550 mm. The teeth are hardened right through. Case-hardened scrapers are also available.Crumbling packer roller

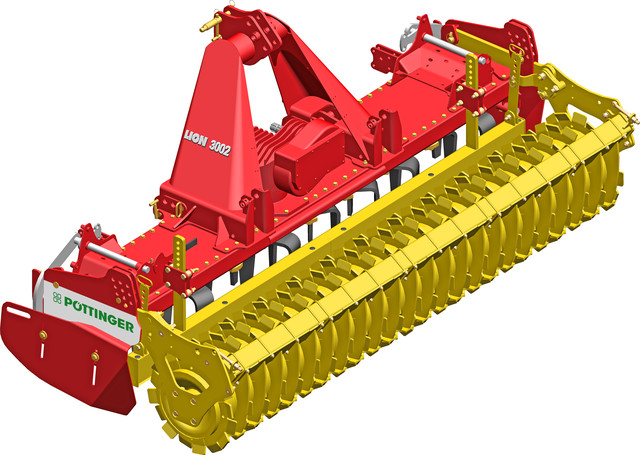

Crumbling packer rollerThe teeth are offset at an angle to the left and right. This roller is especially suitable for heavy, clay soils. The result is a deep packing effect with loose crumbling effect just under the surface. Coated scrapers (standard) prevent soil sticking to the roller.Diameter: 525 mmPack ring roller

Pack ring rollerThe packer rings are fully enclosed and have a diameter of 21.7″ / 550 mm with 8 rings per metre of working width. Due to the small hub diameter, the scrapers do not need to contact the roller or be adjusted. The roller produces a corrugated consolidation effect to promote water absorption and allow the soil to breathe. Ideal for stony, damp conditions and heavy organic residues. Harvest residues remain on the surface of the soil and protect the soil against drying out. Case-hardened scrapers are standard.Prism packer roller

Prism packer rollerThe Prism rings are spaced at 12.5 mm or 5.9 inch. This roller handles all operating conditions, including stony ground and larger quantities of harvest trash. The striped formation of re-consolidation promotes water absorption and breathability of the soil that is subject to less compaction in the gap between the rings. Coated scrapers are standard and help prevent soil sticking to the roller.Rubber packer roller

Rubber packer rollerThis roller is ideal for widely varied ground conditions. Especially for use with trailed implements where the load-bearing capacity of other rollers is near the limit. A diameter of 585 mm and the special profiling allows the soil to be compacted in rows. Coated scrapers (standard) prevent soil sticking to the roller. -

LION - For tractors up to 270 hp

LION – For tractors up to 270 hp

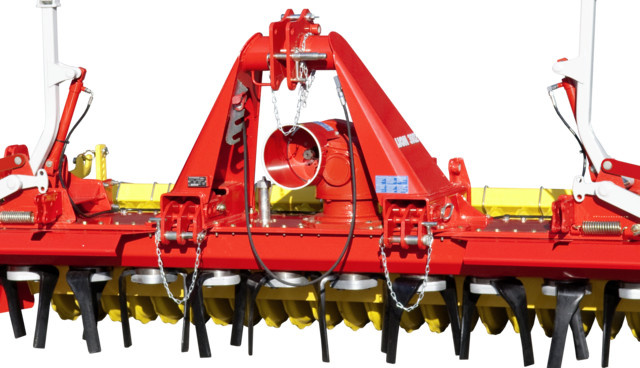

LION 6000Folding series up to 199 kW / 270 hpThese power harrows with working widths of 16.40″ / 5.0 m and 19.68″ / 6.0 m can be folded up for road transport for a transport width of just 8.85″ / 2.70 m.Power harrows for high output

Gear- Category 3 Linkage.

- A robust hydraulic folding frame fitted with torsionally resistant gear troughs.

- Side drive shafts with cam-type clutch P 500 Powerline with long lubrication intervals. Main PTO shaft P 600 Powerline.

- 3-speed lever change gearbox for the best possible power transfer, a rear PTO shaft is standard.

- Heat treated bevel gears run submerged in semi-liquid grease. Quiet running, high quality durable gear train.

- Large dimensioned tapered roller bearings are held in single-piece bearing housings

- Heat-treated tines 0.70″ / 18 mm thick for a working depth down to 11.02″ / 28 cm.

- The rear levelling boards are adjustable vertically and horizontally.

Transport position

Transport position- Two large hydraulic cylinders fold each half of the power harrow through 90° for a transport width of just 8.85″ / 2.7 metres.

- Thanks to the compact design, the centre of gravity is kept close to the tractor.

Downloads

- MACHINERY

- NEW MACHINERY

- USED MACHINERY

- STIHL SHOP

- Segway

- OUR BRANDS

- SPECIALS

- FINANCE

- SERVICING

- BOOK A SERVICE

- CALL 1800 436 3673

- PARTS

- CONTACT US

- 1800 436 3673

- DIRECTIONS

- ABOUT US

- BRANCH LOCATOR

- MEET THE TEAM