MEX 5

for rear or front mounting

Technical data

| MEX 5 Corn | |

| Compare | |

| Length | 2,8 m |

| Width | 2,2 m |

| Weight with corn header | 2150 kg |

| Weight with grass header | 1810 kg |

| Number of knives max. | 10 pcs. |

| Working width with corn header | 2,2 m |

| Working width with grass header | 1,9 m |

| Hight working position | 4,99 m |

| Hight transport position | 3,16 m |

| Chute length | 3,38 m |

| Power requirement with corn header | 150 – 220 hp |

| Power requirement with grass header | 120 – 220 PS |

| Driveline speed with corn header | 1000 rpm |

| PTO speed | 540 rpm |

| Interchangeable wheels with corn header | 19:19 |

| Interchangeable wheels with grass header | 23:19 |

| Chopping length with corn header | 5 / 7 / 9 mm |

| Chopping length with grass header | 11 / 15 / 19 mm |

| Coverage | 0,8 – 1,2 |

Standard Equipment

MEX 5 Corn

| Mounting | Rear three-point |

| Mounting (option) | Front |

| Mounting category | Cat. II / 2 |

| Mounting | 3 point linkage with pins |

| Transmission | shock-absorbed gearbox for 2 flywheel-speeds |

| Flywheel speed | 800 rpm |

| Flywheel | High-output flywheel with 1220 mm diameter Centrally adjustable Tungsten carbide-coated harvester knives |

| Penetration | 470 mm intake width 4 feed and pre-compression rollers Reversible counter blade 3-position chopped length adjustment |

| Protection against foreign objects (option) | Electronic |

| Pick up | Protected by friction clutch Hydraulic cylinder for pick up lifting |

| Corn header | Flattened maize auger for difficult harvesting conditions row-independent for 3 rows |

| Grain pulveriser | Proven highly effective grain pulveriser |

| 2 grain cracker plates 10 adjustable, rasped-surface paddles Deflector per knife |

|

| Chute | Hydraulic chute and flap adjustment, full-length arc for consistent flow of crop |

| PTO shaft guarding | C/w freewheel |

| PTO shaft profile | 1 3/8″ 6-splines |

| PTO speed corn header | 1000 rpm |

| Operation | electronic operation via DIRECT CONTROL |

| Hydraulic connection | 1 x single-acting with free flow return line |

| Electrical connection | 1 x 3-pin Cobo plug |

| Standard equipment includes | Smooth inserts instead of cracker plates for wet corn or grass Warning triangle |

Contact Us

Technology

-

MEX 5 – for rear or front mounting

MEX 5 – for rear or front mounting

Forage harvester for rear or front mounting with row-independent maize headerThe combination of a tractor with reverse drive and the MEX 5 gives you an extremely manoeuvrable, powerful and cost-efficient self-propelled harvester.

- Because the flywheel unit is so compact, you have a clear overview of the header and feed system and the centre of gravity is close to the tractor.

- PTO speed 1000 rpm, flywheel speed 800 rpm.

- Hydraulic side shift system +/- 300 mm

-

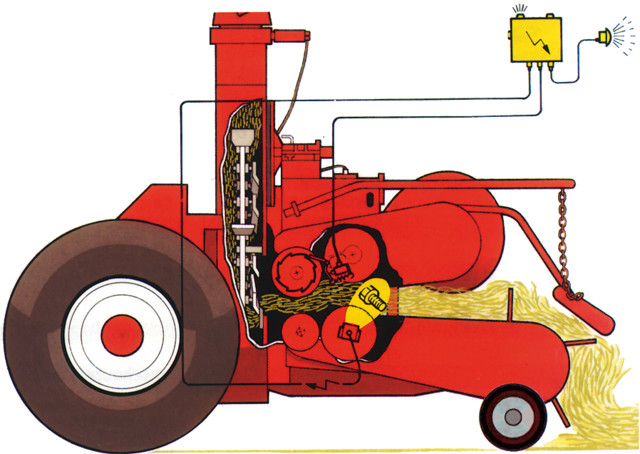

MEX - The proven flywheel system

MEX – The proven flywheel system

The combination of pre-compression feed rollers, exact chopped length with the flywheel and corn cracker guarantees top quality material. All stalks and leaves are finely-chopped and grains pulverised for effective rumination. MEX forage harvesters – acknowledged the world over as the benchmark for best chopping quality. The huge blowing power of the flywheel ensures trailers are filled up right into the furthest corner.

PÖTTINGER flywheel system

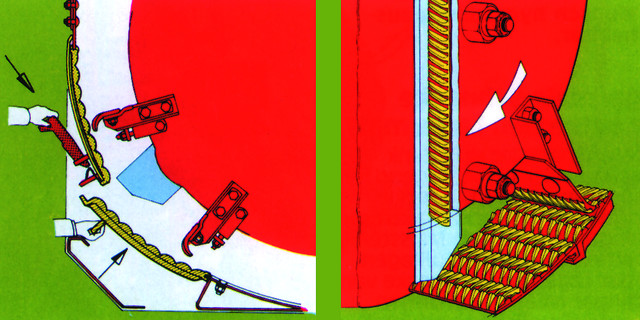

Flywheel system

Grinding disc- Flywheel with 10 centrally-adjustable knives, ideal chopping length is quickly set.

- High chute (up to 4.80 m) and high blowing power plus coated blowing paddles.

- Tungsten-carbide coating on knives and shear bar for smooth and precise chop. The shear bar is also tungsten-carbide coated and reversible.

- Mounting and adjustment functions are separate for rapid replacement without affecting setting.

- Wear plates in the forager housing can be replaced cost-effectively before damage occurs to housing, important on abrasive soils.

Corn cracker – more nutrients from maize

Corn cracker- Exceptional quality forage in all harvesting conditions.

- Rapid adaptation to new crop: allows conversion to harvest green maize in no time.

Three key components:

- Deflector behind each knife.

- Adjustable, rasped-surface blowing paddles.

- Long, sectioned cracker plate, can easily be replaced with smooth plates.

-

Excellent pre-compression – perfect cut

Excellent pre-compression – perfect cut

A uniform and precise chopping action can only be achieved if the crop is heavily compressed before reaching the knives. PÖTTINGER foragers are equipped with four aggressive pre-compression rollers for optimum compaction at the flywheel. This guarantees perfectly chopped material in all operating conditions.

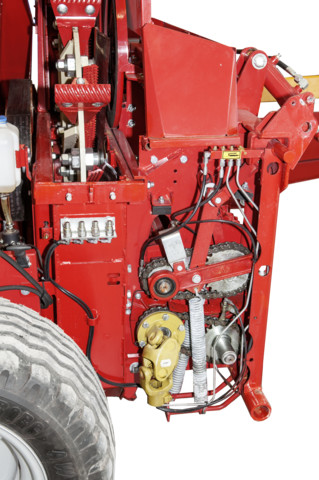

Rugged feed system

Feed systemThe right chopped has to be quickly and easily adjusted to current operating conditions.

- Three different chopped lengths can be quickly set using the three-step belt drive, equipped with hydraulic reversing gear as standard.

- Individual overload protection on each driveshaft to the feed rollers.

Perfect compression roller control

Compression roller control- The PÖTTINGER concept featuring the three-step belt drive system for the pre-compression rollers provides the ideal solution, which includes a reversing gear.

- The two upper rollers are spring-loaded to reliably draw in every type of crop.

- The 470 mm-wide intake channel is critical to achieve high capacity intake.

- The two upper rollers can move completely independently of each other. This ensures continuous compression of the forage right up to the shear bar.

- The crop is heavily compressed by the four feed rollers.

-

Control terminal

Control terminal

Electronic DIRECT CONTROL operator panel

DIRECT CONTROL- Control panel with metal casing and membrane-covered keypad, easy to install with mounting magnet.

- Direct control of: Raise / lower angle of header in relation to chassis , Rotate chute, Fold flap, Reverse feed system, Pivot drawbar.

- Hydraulic connections required: One single-acting remote with pressure-free return for DIRECT CONTROL (suitable for closed, open or load-sensing hydraulics).

Hydraulically folding chute

Hydraulically folding chute- Continuous arc for consistent flow of forage.

- Hydraulic chute rotation and flap adjustment. Chute rotation up to 270°.

- Chute height 4.80 m for 4.0 m-high transport vehicles.

- Can be folded hydraulically for low clearances; no tools required.

- Access platform and two cleaning points provided as standard.

-

Header

Header

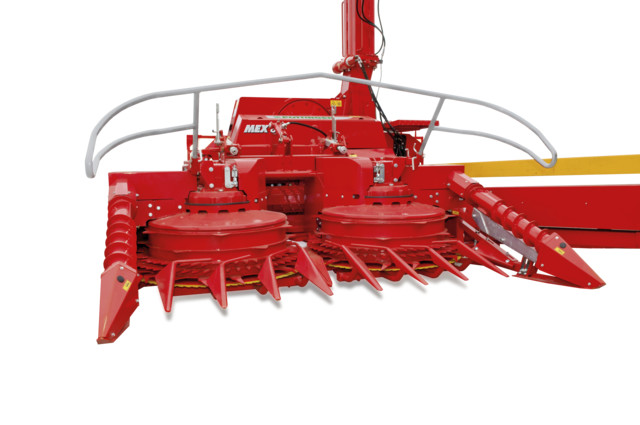

Row-independent maize header

MEX 5 in use

MEX 5 in use Maize header

Maize headerThe maize header enables you to harvest independently of rows or row spacing. As a result the MEX 5 offers manoeuvrable operation like a self-propelled harvester, either with the maize header or pick-up. The MEX 6 is the flexible trailed forager for maize and grass. Tractors up to 220 hp can therefore be utilized very cost-effectively and logistics are extremely easy to organise between the field and the silo.

- Working width 2.0 m (3 rows spaced 0.7 m apart)

- The header is mounted so that it can move up and down independently of the forager for best ground tracking.

- Lowest working height 135 mm.

- Powered by a direct drive system,

- the aggressive rings of teeth on the intake drums ensure loss-free feed in even the most challenging harvest conditions.

- High ground clearance (580 mm) for road transport and headland turns.

- Mechanically-driven feed augers on both sides as standard.

High performance – also in grass

1.90 m wide pick-up

Pick-upHigh loading speeds require a reliable and powerful pick-up. The MEX pick-up with six rows of tines delivers impressive performance – even at high forward speeds and in all harvest conditions. Only a clean crop can guarantee trouble-free fermentation for high quality silage.

- The wide pick-up guarantees maximum performance, even in difficult harvesting conditions such as in damp and short grass.

- The narrow tine spacing means that the forage is collected reliably even at high driving speeds.

- The pick-up tines are swept back to prevent damage to the sward, soil contamination and unnecessary wear on the tines.

- A height-adjustable windguard with a swath roller and the manoeuvrable auger ensure perfect forage flow even when loading is fast and the crop is short and wet.

- The pneumatic jockey wheels (15×6.0-6) touch the ground at the point of tine contact and guide the pick-up perfectly over every undulation.

- Free-wheel clutch for riskless reversing of feed system.

- Overload protection together with the feed rollers.

- For MEX 5 and MEX 6 with row-independent header as an option for harvesting grass.

Metal detector

Metal detectorThis device affords a high level of protection against damage caused through ferrous foreign objects entering the flywheel. If the magnetic field generated in the lower front feed roller is interrupted, the current is switched off causing the relay to close. The feed drive stops and by switching to reverse disgorges the crop along with the tramp metal. -

Easy service

Easy service

Grinding disc- Precise sharpening of the knives takes only a few minutes with the integrated grinding disc. On the MEX 5 the flywheel can be reversed for sharpening.

- The header is quickly removed and the feed system simply folded away. Shear bar and feed rollers are easily accessible for cleaning and servicing.

- MACHINERY

- NEW MACHINERY

- USED MACHINERY

- STIHL SHOP

- Segway

- OUR BRANDS

- SPECIALS

- FINANCE

- SERVICING

- BOOK A SERVICE

- CALL 1800 436 3673

- PARTS

- CONTACT US

- 1800 436 3673

- DIRECTIONS

- ABOUT US

- BRANCH LOCATOR

- MEET THE TEAM