NOVADISC rear mounted disc mowers

With centre pivot suspension – 2.62 to 4.30 m working width

Contact Us

Technical data

-

NOVACAT 262 / NOVACAT 262 ED / NOVACAT 262 RCB / NOVACAT 302

NOVACAT 262 NOVACAT 262 ED NOVACAT 262 RCB NOVACAT 302 Mounting Rear three-point Rear three-point Rear three-point Rear three-point Mounting category Cat, II / 2 Cat, II / 2 Cat, II / 2 Cat, II / 2 Breakaway device Mechanical breakaway device Mechanical breakaway device Mechanical breakaway device Mechanical breakaway device Weight 910 kg 1160 kg 1230 kg 930 kg Working width 2,62 m 2,62 m 2,62 m 3,04 m Transport height 3,6 m 3,6 m 3,6 m 3,8 m Driveline speed with grass header 1000 rpm 1000 rpm 1000 rpm 1000 rpm Mower discs 6 pcs. 6 pcs. 6 pcs. 7 pcs. Mower blades 12 pcs. 12 pcs. 12 pcs. 14 pcs. Power requirement 60 hp 70 hp 70 hp 70 hp Coverage 2,6 ha/h 2,6 ha/h 2,6 ha/h 3 ha/h Outer track – – – – Wear skids 4 pcs. 4 pcs. 4 pcs. 5 pcs. High-cut skids 4 pcs. 4 pcs. 4 pcs. 5 pcs. High-cut skids inside / outside 1 pcs. 1 pcs. 1 pcs. 1 pcs. Swath width without swath discs 1,7 m – – 2,1 m Swath width with 2 swath discs 1,4 m – – 1,7 m Swath width with 4 swath discs 1,1 m – – 1,3 m Swath width with conditioner min – 1,2 m 1,4 m – Swath width with conditioner max – 1,7 m 2 m – Swath forming / Conditioner Swath discs Steel tine conditioner Roller type conditioner RCB Swath discs Swath discs (Standard) without swath discs – – without swath discs -

NOVACAT 302 ED / NOVACAT 302 RCB / NOVACAT 352 V

NOVACAT 302 ED NOVACAT 302 RCB NOVACAT 352 V Mounting Rear three-point Rear three-point Rear three-point Mounting category Cat, III / 2 Cat, III / 2 Cat, III / 2 Breakaway device Mechanical breakaway device Mechanical breakaway device Mechanical breakaway device Weight 1260 kg 1330 kg 1030 kg Working width 3,04 m 3,04 m 3,46 m Transport height 3,8 m 3,8 m 3,99 m Driveline speed with grass header 1000 rpm 1000 rpm 1000 rpm Mower discs 7 pcs. 7 pcs. 8 pcs. Mower blades 14 pcs. 14 pcs. 16 pcs. Power requirement 80 hp 80 hp 80 hp Coverage 3 ha/h 3 ha/h 3,4 ha/h Outer track – – – Wear skids 5 pcs. 5 pcs. 6 pcs. High-cut skids 5 pcs. 5 pcs. 6 pcs. High-cut skids inside / outside 1 pcs. 1 pcs. 1 pcs. Swath width without swath discs – – 2,5 m Swath width with 2 swath discs – – 2,1 m Swath width with 4 swath discs – – 1,7 m Swath width with conditioner min 1,9 m 1,7 m – Swath width with conditioner max 2,7 m 2,5 m – Swath forming / Conditioner Steel tine conditioner Roller type conditioner RCB Swath discs Swath discs (Standard) – – without swath discs -

NOVACAT 352 CF / NOVACAT 352 ED / NOVACAT 352 RCB / NOVACAT 402 / NOVACAT 442

NOVACAT 352 CF NOVACAT 352 ED NOVACAT 352 RCB NOVACAT 402 NOVACAT 442 Mounting Rear three-point Rear three-point Rear three-point Rear three-point Rear three-point Mounting category Cat, III / 3 Cat, III / 3 Cat, III / 3 Cat, III / 3 Cat, III / 3 Breakaway device Hydraulic breakaway device Hydraulic breakaway device Hydraulic breakaway device Hydraulic breakaway device Hydraulic breakaway device Weight 1460 kg 1340 kg 1390 kg 1040 kg 1080 kg Working width 3,46 m 3,46 m 3,46 m 3,88 m 4,3 m Driveline speed with grass header 1000 rpm 1000 rpm 1000 rpm 1000 rpm 1000 rpm Mower discs 8 pcs. 8 pcs. 8 pcs. 9 pcs. 10 pcs. Mower blades 16 pcs. 16 pcs. 16 pcs. 18 pcs. 20 pcs. Power requirement 120 hp 120 hp 120 hp 90 hp 110 hp Coverage 3,4 ha/h 3,4 ha/h 3,4 ha/h 4 ha/h 4,5 ha/h Outer track – – – – – Wear skids – 6 pcs. 6 pcs. 7 pcs. 8 pcs. High-cut skids 6 pcs. 6 pcs. 6 pcs. 7 pcs. 8 pcs. High-cut skids outside 1 pcs. – – – – High-cut skids inside / outside 1 pcs. 1 pcs. 1 pcs. 1 pcs. 1 pcs. Swath width without swath discs – – – 3,2 m 3,6 m Swath width with 2 swath discs – – – 2,7 m 3 m Swath width with 4 swath discs – – – 2,3 m 2,6 m Swath width with conditioner min – 2,2 m 2,2 m – – Swath width with conditioner max – 3,1 m 3 m – – Swath forming / Conditioner auger Steel tine conditioner Roller type conditioner RCB Swath discs Swath discs Swath discs (Standard) – – – without swath discs without swath discs

Standard Equipment

-

NOVACAT rear-mounted mowers with vertical transport position

Mounting Rear three-point Mounting option Mounting stub Mounting category Cat. II / 2 Cat. III / 2

PTO shaft guarding Fitted with slip clutches PTO shaft profile 1 3/8″ 6-splines Protection system Hinged front guard Side guards can be folded Hydraulic connection 1 x single-acting for the lifting in the headland position 1 x double acting for lifting into the transport position and the lower linkage arm

Electrical connection 1 x 7-pin lighting plug for warning signs with lighting Standard equipment includes Operator’s manual Spare parts list

Replacement blades

Blade changing tool

-

NOVACAT rear-mounted mowers with horizontal transport position

Mounting Rear three-point Mounting option Mounting stub Mounting category Cat. III / 3 PTO shaft guarding Fitted with slip clutches PTO shaft profile 1 3/8″ 6-splines Protection system Hinged front guard Side guards can be folded Hydraulic connection 1 x single-acting for the lifting in the headland position

1 x double acting for the hydraulic rear pivot systemElectrical connection 1 x 7-pin lighting plug for warning signs with lighting Standard equipment includes Operator’s manual

Spare parts list

Replacement blades

Blade changing tool

High-cut skids cutting height + 20 mm NOVACAT 352 CF

Downloads

Technology

-

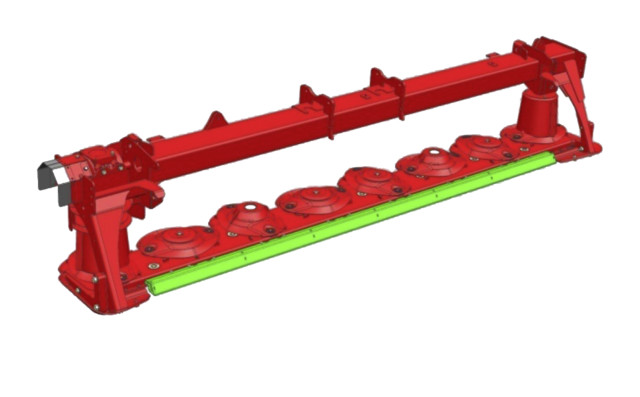

PÖTTINGER cutter bars

The heart of PÖTTINGER disc mowers is the cutter bar, proven over thousands of cuts in the field. Disc mower cutter bars are developed and built at the company’s main plant in Grieskirchen – a quality product made in Austria. First-class cutting quality, low drag resistance and strength are the trademarks of these cutter bars. Engineered details guarantee you reliable operation and contribute significantly to an extended service life.

Optimum crop flow – clean forage

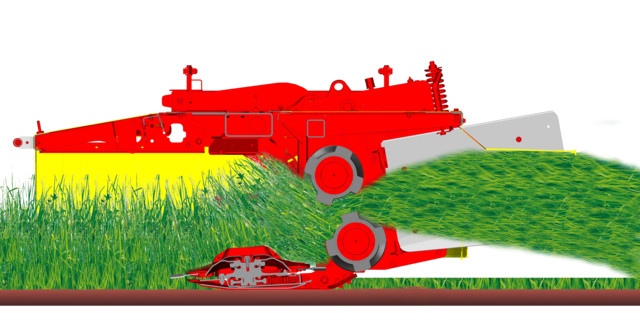

Optimum crop flow

The rounded, low profile front edge lets the cutter bar glide smoothly over the ground and separates the crop tidily from the sward. The conveyor effect has been improved by the rounded conical surfaces of the mower discs. The crop flows through smoothly and uniformly, maintaining full cutting capacity in all operating conditions. Integrated paddles keep the cutter bar surface clean. PÖTTINGER guarantees trouble-free downhill mowing, even on steep slopes.

Perfect cutting quality

Sleek cutter barThe sleek cutter bar design is only 28 cm deep, perfect for enabling the best possible ground tracking. The mower blades rotate very close to the surface of the cutter bar and the counter knife. The optimised overlap of blade paths ensures a clean and uniform mowing pattern.

Engineered to impress

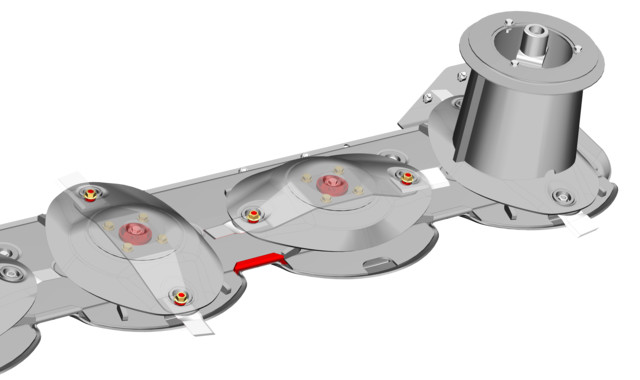

Mower discsDurable mower discs

The oval, low profile mower discs are made of hardened fine-grained steel. Quick-change blades make maintenance easy.

Optional feed conesThese improve the crop flow and enable swath formation.

Stub shaftHigh-strength stub shafts

The strong stub shafts are bolted to the gears and are thus easy to replace when required.

Heavy-duty bearings

Durable, twin race tapered bearings with a theoretical bearing spacing of 60 mm are extremely stress-resistant.

TRI DRIVE – Optimised gears

Gear pairsReliable power transmission

The cutterbar gear drive runs in a straight line with virtually the same sized gears. All gears are hardened and machined for smooth running and a long service life.

- New gear pairs with the same diameter 39/50

- Three teeth in contact – better power transmission – softer starting characteristics.

- New surface on gears ensures smoother running and a reduction in noise level.

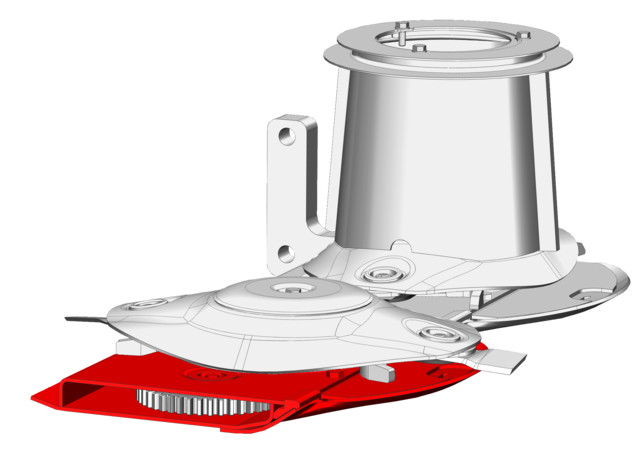

Wear resistant skids

Skids

High cut wear skid

Wear resistant skidWide skids made from hardened boron steel to resist impact and prevent the build-up of soil. Because the underside of the cutter bar is smooth with contoured skids inside and outside, it protects the sward even on tight corners.

As an option, you can fit additional wear skids to protect the underside of the cutter bar. The bolted skids can be easily changed if required.

Optional high-cut skids can be mounted to increase the cutting height from 30 to 120 mm. Their large radius and wide surface area make them especially wear resistant.

- High-cut skid + 20 mm, the universal skid especially for stony soil.

- High-cut skid + 40 mm, especially for whole crop.

- NEW: High-cut skids for the outer pairs of skids.

Top quality

Cutter bar manufactured from the best quality steelThe cutter bar is made from the best quality steel. The metal plate is precision laser-cut and robot-welded before machining at the state-of-the-art CNC machining centre.

- The blade post is bolted to the mower disc. This can be replaced cost-effectively if required.

- The counter knife is clamped in place, meaning it is also easy to replace.

Easy with quick-change blades

Change bladesChange blades quickly and easily: Press down the spring clip with the blade changing tool and replace the blade.

- The blade is locked securely in place by the spring clip.

- Lengthy, tough operation demands the best blade quality, which is why original PÖTTINGER blades are made from high-quality blade steel.

- A handy blade box provides space for replacement blades.

- A handy blade box provides space for replacement bladeThe blade pin is bolted to the mower disc. This can be replaced cost-effectively if required.

Maintenance-friendly

Easy access

Simple designPractical modular design

The bearing hub assembly and fittings are reliably sealed by rubber o-ring seals. The hub assembly can be removed as one unit, while the idler gears are easily removed through the openings – it could not be more straightforward.

-

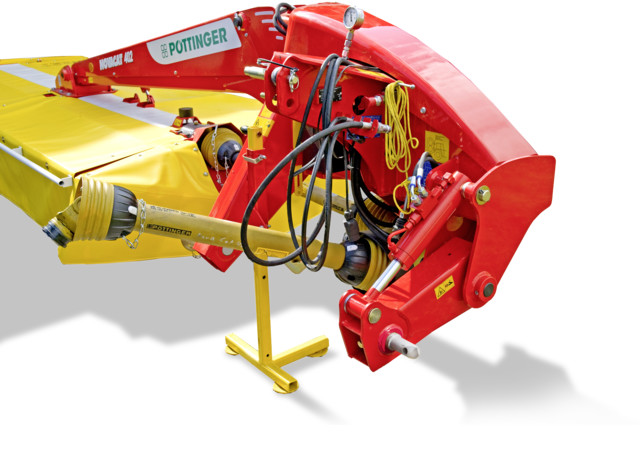

Mounting and collision safety device

Hitching up made easy

Hydraulic lower linkage arm

The hydraulic lower linkage arm makes it easy for you to hitch up without having to adjust the linkage struts on the tractor. This ensures you always have the right weight alleviation and plenty of ground clearance at headlands. A turnbuckle provides the right setting on the NOVACAT 262 and 302 without conditioner.

Variable hitching made easy

Thanks to the adjustable mounting pins, these mowers can be hitched up to a wide range of tractor types quickly and easily. As a result you make full use of the whole mowing width.

- Practical PTO shaft holder makes hitching up easier.

- A handy blade box provides space for replacement blades.

- The blade tool is kept on the machine.

Anti-collision device

Anti-collision device

If the mower collides with any obstacles, the cutter bar can fold back through a wide arc to the rear. The triggering force is adjustable. A hydraulic collision safety device is also available as an option.

-

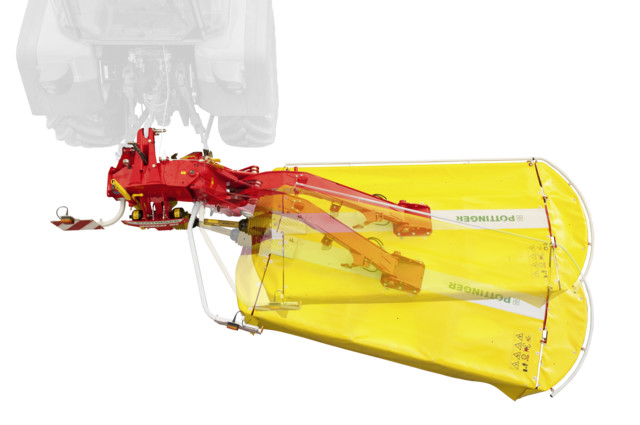

Rear-mounted mowers with vertical transport position

NOVACAT 262 / 262 ED / 262 RCB / 302 / 302 ED / 302 RCB

NEW: NOVACAT 352 V

Drive system

The driveline transmits power directly from the PTO shaft to the angular gearbox and then via a double universal joint in the inner drum stress-free to the gear on the first mower disc. Exceptional smooth running is guaranteed.

- A friction clutch and freewheel provide optimum protection.

- The gears run submerged in oil.

Cutter bar suspended at both ends

Mounting points at each end of the cutter bar protect it against twisting. As a result, the gears and bearings are subjected to less stress for smoother operation and a long service life.

Practical transport position

Transport positionThe cutter bar is raised using double-acting spool valves. A low transport height is achieved by folding the mower through 115°. The centre of gravity is on the tractor’s centreline and the driver has a clear view to the rear in both side mirrors.

Optimised ground trackingDeveloped by PÖTTINGER – the “floating cut” is the decisive factor.

Since the mid-80s, our mower developments have focussed on the “floating cut”. Optimised ground tracking and sward conservation thanks to reduced pressure on the ground is what farmers demand on all mowers.

Centre pivot mounting for optimised ground tracking

NOVACAT centre pivot mountingThe NOVACAT centre pivot mounting supports the cutter bar evenly over the entire cutting width. This reduces the power input required – an enormous advantage when mowing with a conditioner. The wide +/- 22.5 degree arc of movement enables easy mowing on rough surfaces and embankments.

Effective weight alleviation

ReliefHydraulic weight alleviation provides uniform ground pressure over the whole cutter bar width. The pressure of the cutter bar on the ground can be infinitely-variable adjusted depending on the condition of the ground and the conditioner or swath formers fitted. No additional filling hose is required and you can read the current pressure at the pressure gauge. In dry, hard conditions the ground pressure can be increased to stabilise the cutter bar at high driving speeds. Damp, soft conditions require a reduction in ground pressure to ensure the best ground tracking and conservation of the sward.

-

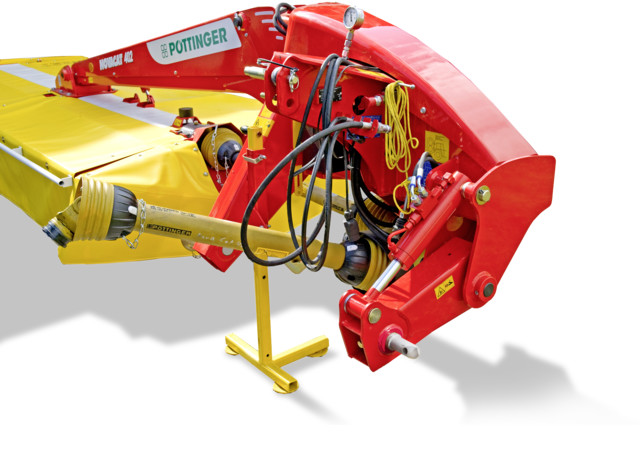

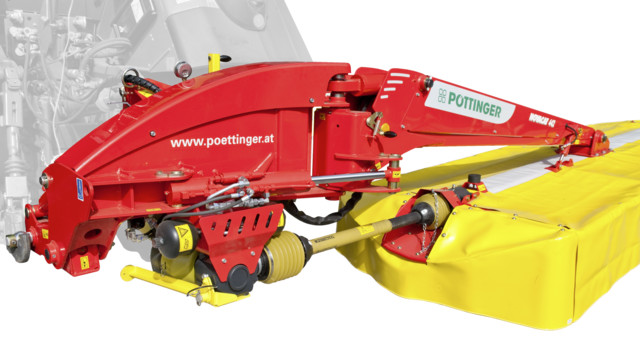

Rear-mounted mowers with horizontal transport position

NOVACAT 352 / 352 ED / 352 RCB

NOVACAT 402 / 442

Top performance for rear mowers

Mounting on tractorThe top end of our rear-mounted mower range without conditioners is represented by the NOVACAT 402 and 442 with working widths of 3.88 m and 4.30 m. NOVACAT 402 and 442 deliver high output and are designed especially for tractors without a front PTO.

NOVACAT 352, 352 ED and 352 RCB have a mowing width of 3.46 m. Our NOVACAT 352 with tine-type or roller-type conditioner enable a front/rear combination with conditioners to mow up to 6.20 m wide.

Perfect linkage

Lower linkage armThe hydraulic lower linkage arm guarantees easy hitching even with these wide mowers and plenty of ground clearance at headlands.

HEAVY DUTY cutter bar

HEAVY DUTYAn additional cutter bar reinforcement is offered as an option for especially stony areas. Standard on NOVACAT 402 / 442.

Feed drumsPaddle drums at both ends of the cutter bar place a neat swath leaving a tidy wheel track clear. The swath can be divided with two feed drums (optional). As a result, the tractor is driven over the forage-free area rather than the swath.

Narrower, lower transport

Transport position

The mower is swung hydraulically to the rear for transport. The pivot device also doubles as a breakaway device to protect the machine from collision. The cutter bar is also secured using a stabilizer cylinder.Flexible

With the cutter bar mounting rotated through 180° it can be adapted to match front mower cutting widths of 3.0 and 3.50 m.50 cm ground clearance

Ground clearanceAt the headland, ground clearance is 50 cm. During lifting, the cutter bar is secured using a stabilizer cylinder. This makes it easier to drive over swaths and provides stability during transport.

-

NOVACAT 352 CF - Swath merging with cross flow auger

NOVACAT 352 CF – CROSS FLOW Swath merging without conditioner

Cross flow augerWith the NOVACAT 352 CF, PÖTTINGER now offers a cost-effective and lightweight system for merging swaths. Its low weight and low power requirement greatly reduce fuel consumption.

Cost effective system

CROSS FLOW

With the NOVACAT 352 CF you profit from much lower investment costs for a swath merging system. This innovative solution does not need a conditioner and enables a weight reduction of 30 % compared to conventional systems. Thanks to its low power requirement, you save fuel costs.

Simple and Flexible

NOVACAT 352 CFBecause the cross conveyor auger runs inside a closed casing, all the crop is conveyed to the swath without losses. Swath curtain as option.

It is easy to switch between wide blanket or swath placement by manually opening the cover.

-

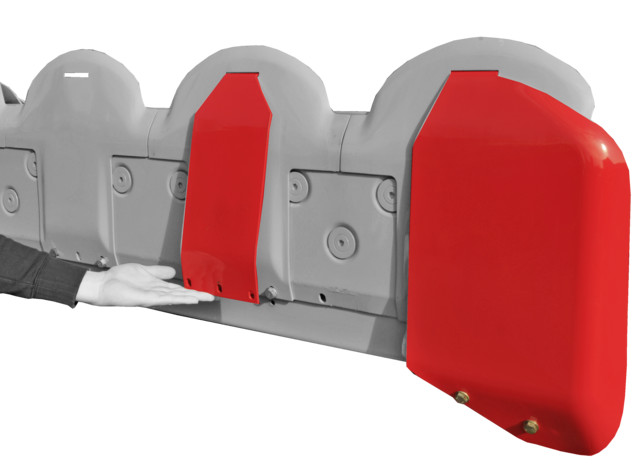

Easy service

Best accessibility

Blade changingWe take ease of maintenance seriously. The guards fold well away to provide optimum access to the cutter bar. Now you can change blades quickly and easily.

Save time with maximum service friendliness

Blade boxQuick-change blades for a clean and smooth cut

- Press down the spring clip with the blade tool and replace the blade.

- The blade is locked securely in place by the spring clip.

- The blade pin is bolted to the mower disc. This can be replaced cost-effectively if required.

- Long, tough jobs demand the best quality blades. PÖTTINGER blades are made from high-quality knife steel.

- A handy blade box provides space for replacement blades.

Low maintenance drivelineWe have increased driveshaft lubrication intervals to 150 hours and the PTO shafts are easily accessible. As a result they are easy to service. Practical PTO shaft holder makes hitching up easier.

Drive from the field onto the road without leaving the cab

Strong side guardsThe side guards are strong full-length pressed steel parts. Hydraulic folding is available if required.

Space-saving parking

Parking supportsNOVACAT 262, NOVACAT 302 and NOVACAT 352 V

With the optional parking stands they find room in the smallest spaces.

The parking stands are CE approved.

-

Models with conditioners

ED tine conditioner

EXTRA DRY

Tine rotor

ConditionerThe EXTRA DRY conditioner is a joint development with the Institute of Agricultural Engineering (IMAG-DLO) in Wageningen (Holland) that started in 1997 to prove there is better way. Your forage dries measurably faster thanks to the adjustable conditioning intensity and wide placement.

V-shaped steel tines of hardened steel guarantee a continuous flow of crop and an extended service life. The tines are mounted on rubber elements in a spiral configuration on the conditioning roller.

EXTRA DRY drying accelerator

The tine rotor propels the forage across an adjustable conditioning plate. Adjustable guide vanes distribute the flow of crop over the whole mowed width. The forage is then deposited in a uniform and airy blanket by the wide-spread hood. Adjustable guide vanes distribute the flow of crop over the whole mowed width. Pivoting swath plates can be used to form a swath.

Even more flexibility

Power is transmitted from the cutter bar gearbox to the rotor by drive belts with a spring-loaded belt tensioner. If the conditioner is not required, it can be removed.

- The drive belts are easily detached for removing the conditioner

- The drive system is reliably protected against contamination.

- The greasing points are located on the outside for easy access.

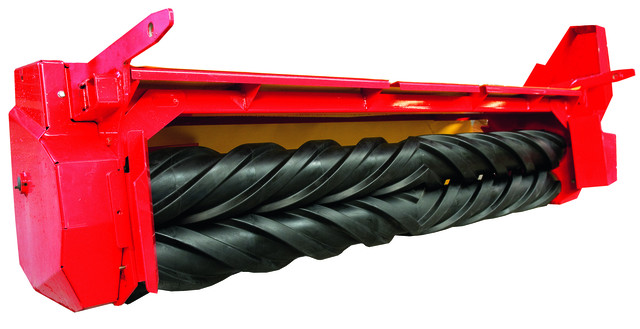

RCB roller conditioner

RCB roller conditionerProfitable yields in dairy farming are only possible with high-quality base forage. Quality nutrients in the forage increases milk output at the same time as reducing the costs of concentrates. For leafy types of plant, PÖTTINGER offers a proven conditioner with crimping rollers.

The roller conditioner is especially suitable for alfalfa and all types of clover due to its precision conditioning capabilities. The rollers intermesh to crimp the stalks and produce a uniform blanket of forage. The roller profile is spiral-shaped.

Conditioner profileReliable and durable

The rugged central tube has a diameter of 140 mm and a wall thickness of 5.6 mm. The Polyurethane profile is vulcanised onto the central tube of the roller. The outer diameter is 200 mm. The conditioner profiles are harder than rubber and therefore particularly resistant to wear.

Reliable drive system

- Both rollers are driven.

- Contamination-free, low-maintenance toothed drive belt on roller conditioner.

- The inter-meshing rollers crimp the stalks to produce a uniform blanket of forage

- The upper roller is height-adjustable so that the gap between the rollers can be set.

- The conditioner pressure can be adjusted on both sides via coil spring adjusters.

- The greasing points are located on the outside for easy access.

- MACHINERY

- NEW MACHINERY

- USED MACHINERY

- STIHL SHOP

- Segway

- OUR BRANDS

- SPECIALS

- FINANCE

- SERVICING

- BOOK A SERVICE

- CALL 1800 436 3673

- PARTS

- CONTACT US

- 1800 436 3673

- DIRECTIONS

- ABOUT US

- BRANCH LOCATOR

- MEET THE TEAM