HIT with 4 rotors

HIT with 4 rotors

From 4.40 to 5.20 m working width

The highest requirements of small to medium-sized farms are met in full with our 4-rotor tedders. Designed for all forage types, these machines provide you with optimum distribution quality and a perfect crop take-up.

Technical data

| HIT 4.54 | |

| Working width | 5,4 m |

| Working width DIN | 5,2 m |

| Transport width | 2,85 m |

| Transport height | 3 m |

| Parking height | 2,6 m |

| Weight | 550 kg |

| Power requirement | 35 hp |

| Number of rotors | 4 pcs. |

| Number of arms per rotor | 6 pcs. |

| Type of tines | unequal leg length |

| Quality of tines | Super C |

| Tine security system | HEAVY DUTY as standard |

| Transmission | PTO shaft |

| Rotor diameter | 1,67 m |

| Fenceline spreading system | rigid |

| Tyres – rotor outside / inside | 16 x 6,5-8 / 16 x 6,5-8 |

Contact Us

Standard Equipment

-

HIT

HIT Mounting Rear three-point Mounting option Three point linkage c/w enclosed lower link pins Mounting category Cat. II / 2 PTO shaft guarding with cam clutch PTO shaft profile 1 3/8″ 6-splines Hydraulic connection 1 x single-acting for the lifting system Electrical connection 1 x 7-pin lighting plug for warning signs with lighting Standard equipment includes Operator’s manual Spare parts list

-

HIT T

HIT T Mounting Trailed hydraulic folding Mounting option Mounting brackets on lower linkages Mounting category Cat. II / 2 PTO shaft guarding with cam clutch PTO shaft profile 1 3/8″ 6-splines Hydraulic connection 1 x single-acting for the lifting system Electrical connection 1 x 7-pin lighting plug for warning signs with lighting Standard equipment includes Operator’s manual Spare parts list

Technology

-

DYNATECH The new rotor technology

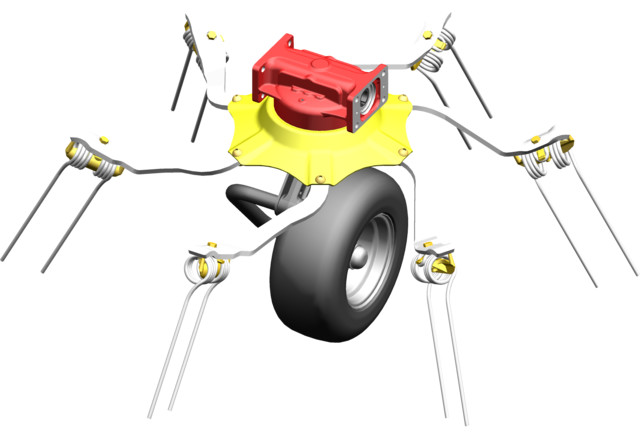

DYNATECH rotor

Yet another PÖTTINGER innovation: The unique swept-back tine arms guarantee a tidy distribution pattern. High performance is built in to our mounted and trailed HIT tedders.

DYNATECH for all HIT models

Rotors with a diameter of 1.30 m and five arms are ideal for young, short forage. Rotors with a diameter of 1.42 m or 1.67 m and six arms are designed for different working widths and operating conditions.

Four times as clean

- Forage pick-up – small rotor diameters guarantee clean crop pick-up

- Forage – optimum ground tracking of each rotor for clean forage

- Spread pattern – ideal spreading angle for a uniform blanket of clean forage

- Machine – no snagging thanks to the sleek design of the rotor units

The curved shape of the tine arms is unique.

Guiding the tines in a sweeping movement means less stress on the bearings. At the same time the trailed tines move more smoothly, are softer and handle the forage more carefully. The curved shape prevents forage from building up in the tine arms and wrapping around the rotors.

-

HEAVY DUTY tines

More safety

- The bolted mounting ensures a secure fit.

- A tine security system is standard – to cover all eventualities.

Tines with a longer service life

- An arched mounting supports the tine springs.

- Plenty of space between the tine springs and the tine arms allows for the best elasticity and movement.

- Strong Super-C quality tines.

Clean forage

Offset tine lengths pick up the forage uniformly and contribute significantly to improved tedding quality. Choose between two angles by rotating the mounting through 180°. The cleanest possible forage is guaranteed.

High-strength tine arm mountings

The rotor plates are made of heavy-duty, thick-walled pressed components with precise placement for the tine arms. In addition, the tine arms are also bolted to the rotor hubs to ensure an extremely secure mounting.

The tines and tine arms are subject to the highest stress during tedding. The solid flat bar tine arms feature indentations to ensure that the tines remain securely in place.

-

MULTITAST

Unique ground tracking

Ground tracking and forage protection are the key objectives of HIT rotary tedders. An optional jockey wheel on the pivoting headstock tracks the ground immediately in front of the tine path and responds to each undulation. The result: Clean forage, lower raw ash content and improved livestock health.

Always one wheel ahead

The jockey wheel guides the rotors over bumps in the ground. This ensures that the working depth is always set correctly. You are now able to drive faster and can achieve a higher output as a result. The sward is protected and the tines last much longer. The additional jockey wheel is especially recommended for working on slopes.

- The jockey wheel can be mounted in several different positions to the left or right using the pin-in-hole matrix on the headstock.

- The top link connects to the slotted hole on the headstock.

- No tools are required to adjust the height.

- On trailed machines, the jockey wheel is mounted on the drawbar.

-

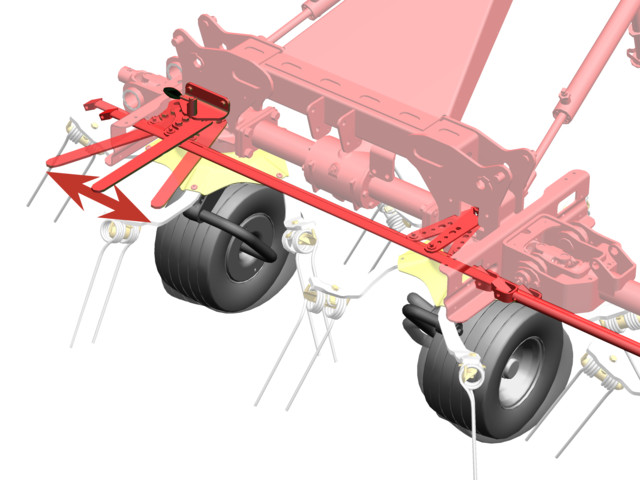

Fenceline tedding – easy and convenient

Fenceline spreading system

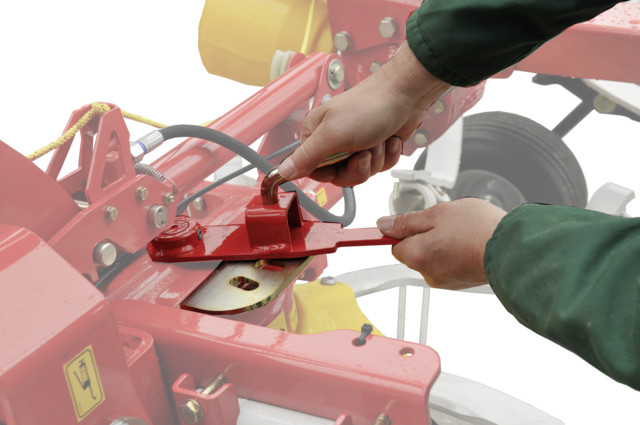

Mechanical fenceline tedding system

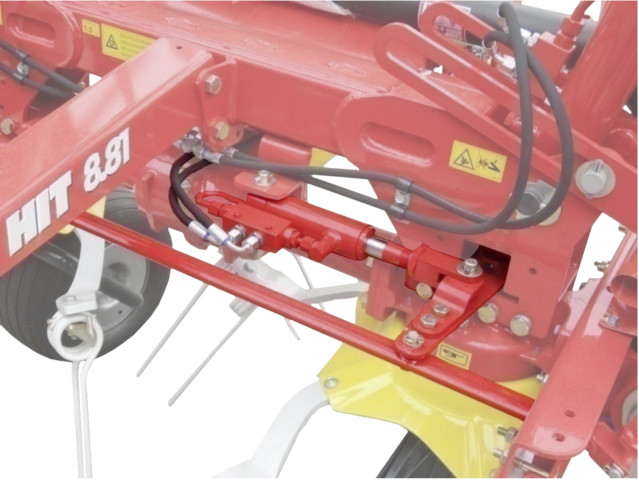

Fenceline tedding cylinder

Actively setting the wheels at an angle causes the tedder to run diagonally so the forage is directed onto the mown area. Neighbouring crops remain untouched. Because the wheels can be set to the left or right, fenceline tedding can be activated in any driving direction.

Mechanical fenceline tedding system

HIT 4.47 / HIT 4.54 / HIT 4.54 T

The wheels on all four rotors are set individually by hand.

Lever positions centre – left – right

The most cost-effective version

If you do not require a fenceline tedding system, the wheels are mounted securely to the rotor casing as standard using roll pins.

-

Durable and reliable

Durable and reliable over many years

Backlash-free drive joints

Sealed single and double constant velocity joints ensure consistent, smooth, backlash-free transmission. This ensures that the tines pick up the crop at a precise frequency and distribute it evenly. At the same time, they can be rotated in any position, eliminating the possibility of operator errors.

Clevis-type frame hinges provide each rotor with the freedom of movement for perfect ground tracking. Fitted with plain bushes, they are easy to lubricate.

HIT – Rugged rotor transmissions

Drive shaft

- Large gears and bearings ensure smooth operation.

- The closed angular gear units are equipped with grease lubrication systems.

- No oil leaks possible.

- The joints are mounted on a splined shaft.

Runs smoothly and protects the ground

The large 16 x 6.5-8 flotation tyres on each rotor ensure smooth running and protect the sward, even over soft and bumpy ground. Each wheel is fitted with a cover that also serves as anti-wrap guard.

HIT 8.91 T / HIT 8.9 T / HIT 10.11 T / HIT 12.14 T

The two inner rotors on the HIT 8.81 and HIT 8.91 are fitted with 16 x 9.50-8 flotation tyres. This improves weight distribution during operation and conserves the soil.

Adaptable for neat results

The rotors can be moved into three positions without the need for tools. You can adapt the rotors to the forage conditions quickly and easily. A uniform and tidy spread pattern is ensured as a result.

Automotive paintwork quality

CIP and powder coating guarantee elasticity and durability. Together with attractive colours and modern design, a high resale value is ensured.

-

Four rotor tedder

These tedders offer working widths (DIN) of 4.40 m and 5.20 m, feature a highly compact construction and are ideal for working on slopes. Compact advantage. Six tine arms per rotor guarantee an optimum spread pattern for every forage.

Very short headstock

HIT mounted tedders are known for their short headstock. This brings the centre of gravity closer to the tractor. Less lifting power is needed and driving safety is increased.

For optimum cornering

- Tedders with pivoting headstocks follow in the tractor’s tracks without swivelling out.

- The pivoting headstock with a heart-shaped pivot pin brings the machine into the centre position when it is raised.

- A slotted hole is provided for operation with a jockey wheel and rigid top linkage.

- A practical PTO shaft holder makes hitching and unhitching a great deal easier.

- The transport interlock enhances safety on the road.

Compact and safe during transport

The hydraulic rotor raising system provides convenient operation from the tractor seat. In the transport position, the rotors can be rotated inwards to ensure safe transport and space-saving parking. Warning signs and road lights are standard.

-

HIT 4.54 T – four rotor tedder

HIT 4.54 T – four rotor tedder

The trailed HIT 4.54 T delivers professional tedding with small tractors. At the headland and during transport, the rotors are raised by a hydraulic cylinder inside the drawbar.

Fenceline tedding

All wheels are pivoted by hand for fenceline tedding.

Downloads

- MACHINERY

- NEW MACHINERY

- USED MACHINERY

- STIHL SHOP

- Segway

- OUR BRANDS

- SPECIALS

- FINANCE

- SERVICING

- BOOK A SERVICE

- CALL 1800 436 3673

- PARTS

- CONTACT US

- 1800 436 3673

- DIRECTIONS

- ABOUT US

- BRANCH LOCATOR

- MEET THE TEAM